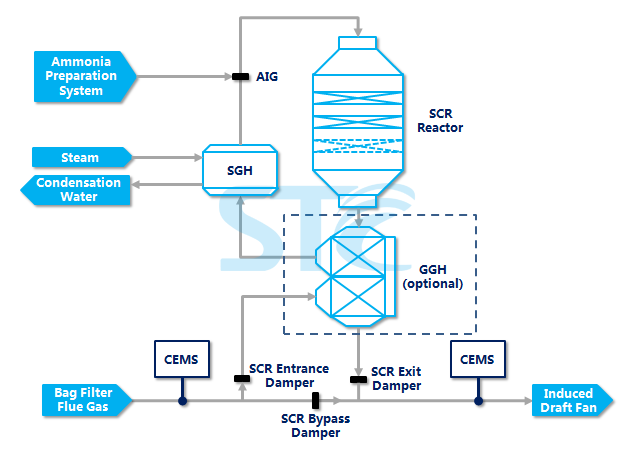

SCR Denitration System Process IntroductionSCR Denitration System Process IntroductionSTC has invented the first high-efficiency SNCR and low-temperature SCR combined process in China, aiming specifically at waste incineration. In the combined process, the low cost of SNCR process and the high denitration rate of the Low-Temperature SCR process have been effectively combined and substantially improved. The combined process can achieve a denitration rate of up to 95% and an ammonia slip rate of nearly zero. Meanwhile, this combined process caneffectively control dioxins and reach a gaseous dioxin removal rate of 90% under the premise of denitration performance. V-Ti-based catalysts are adopted in the SCR denitration system. Catalysts of granular type, honeycomb type, corrugated honeycomb type,etc. are applicable in this system. The denitration system requires a continuous operation temperature range from 170℃ to 230℃. Ammonium hydroxide (20%) is first gasified into ammonia gas in the evaporation system, and then be injected into the outlet flue gas of SGH through the AIG (Ammonia Injection Grid). After uniform mixing with the flue gas, ammonia gas will then enter the SCR system, reacting with NOx in flue gas and producing harmless nitrogen and water steam in the presence of catalyst. The treated gas after denitration is then discharged through the induced draft faninto the stack. The chemical equations for the SCR denitration system are as follows: 4NH3+4NO+O2 ----> 4N2+ 6H2O NO+NO2+2NH3 ----> 2N2 + 3H2O In the presence of catalysts, dioxins in the flue gas are decomposed into harmless carbon dioxides, water and a trace of hydrogen chloride in the oxidizing reaction with oxygen. |