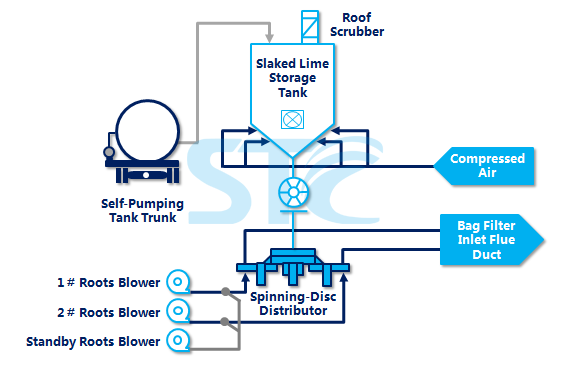

Dry Process IntroductionDry Process IntroductionIn dry injection deacidification system, the reactant is injected into the inlet flue duct of the bag filter by means of pneumatic transmission and is fully mixed with the flue gas before entering the bag filter. The solid reaction bed was formed on the filter-bag, removing the acid gas in the flue gas (SO2, HCl). Atomization spray system is installed on the top of the semi-dry scrubber. When the semi-dry scrubber breaks down or stops operation for repairing, the atomization spray system is used to reduce the flue gas temperature. In this case, the dry process could reach the optimum reaction temperature in order to meet the flue gas emission standards. Slakedlime or sodium bicarbonate is normally adopted as the reducing agent. The reaction temperature is about 150℃ for slaked lime and about 180℃ for sodium bicarbonate. The system can not only remove the acid gas in the flue gas, but also protect the bag filter during the starting-up process of the waste incinerator. Lime powder can be injected through the dry process for bag filter pre-coating, which can prevent the blocking of filtration poles by oil contamination and fly ash and can thus protect the bag filter. |